Time & Motion Study

- Home

- Service Post

- Time & Motion Study

What is a Time & Motion Study?

A Time and Motion Study is a structured technique used to assess and enhance operational workflows by breaking down tasks into smaller actions, timing them, and identifying inefficiencies. The goal is to streamline operations, boost manpower effectiveness, and reduce overhead costs. Widely applied in manufacturing, logistics, and services, these studies enable organizations to optimize resource use, define clear benchmarks, and improve overall performance.

How to Prepare for a Time and Motion Study

Laying the groundwork is vital to ensure the accuracy and impact of a Time and Motion Study. Follow these steps to set up effectively

Set Clear Objectives

Determine what you want to improve: output, efficiency, or cost.

Build the Right Team

Engage experienced analysts or skilled time and motion experts.

Select Focus Areas

Identify departments or processes that show signs of inefficiency.

Collect Baseline Metrics

Gather current data for comparison.

Keep the Team Informed

Communicate openly with staff to gain cooperation and build trust.

Choose Tools & Techniques

Decide on manual or digital methods like video recording or stopwatch tracking.

Implementation of Time and Motion Study

The true value of the study lies in its execution. A robust implementation plan includes

Workflow Reengineering

Adapt operations based on insights to boost productivity.

Employee Training

Prepare staff to adapt and thrive with revised processes.

Tech Enablement

Introduce automation or IoT tools to support efficiency.

KPI Setup

Track progress with new metrics for sustained success.

Ongoing Review

Maintain gains through regular evaluations and adjustments.

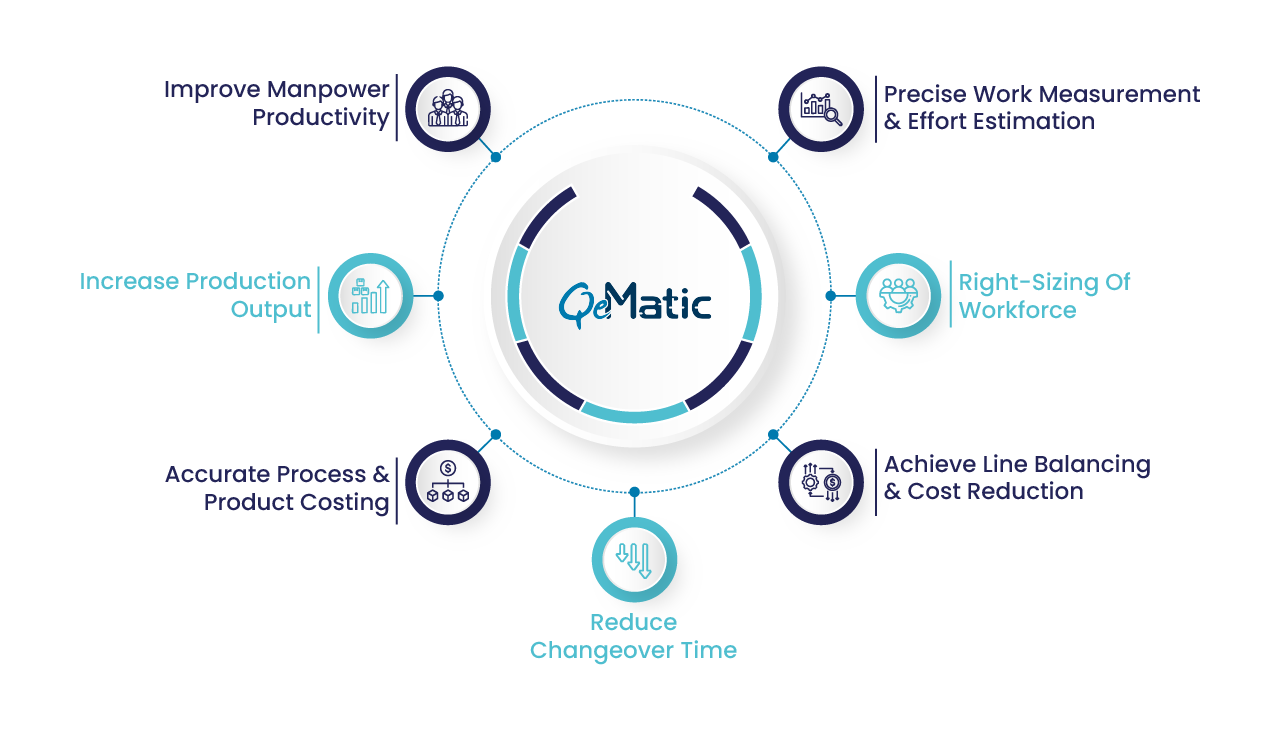

Applications of Time and Motion Study

This methodology can elevate productivity and cost-efficiency across industries. Some key applications include

- Enhancing manpower efficiency through task refinement

- Boosting production rates without sacrificing quality

- Estimating effort and time accurately for task planning

- Optimizing workforce allocation and headcount

- Lowering costs by removing waste and redundancy

- Streamlining assembly lines for peak performance

- Cutting down on changeover and transition time

- Supporting employees with structured, less strenuous workflows

- Designing equitable wage systems based on real effort

- Balancing workloads to prevent bottlenecks

How to Conduct a Time and Motion Study

Execution is key. Here’s how the process unfolds

Why QeMatic for Time and Motion Studies?

At QeMatic, we specialize in customized Time and Motion Studies to unlock hidden potential within your operations. Our team brings data-driven analysis, industry insights, and hands-on implementation expertise to every project.

Pinpoint Inefficiencies

Discover hidden gaps and performance drains.

Actionable Recommendations

Get tailored strategies backed by real-time data.

Optimal Resource Planning

Ensure the right tools, people, and timing.

Sustained Results

Implement monitoring tools for long-term improvement.

Upskill Your Teams

We provide knowledge transfer to keep momentum going.

Proven Results

QeMatic’s proven methodologies have driven exceptional outcomes, such as

Ready to reimagine your operations? Our Time and Motion Study services are your first step toward leaner, smarter, and more productive workflows.

Discover how our Supply Chain Consulting Services can further amplify your results.